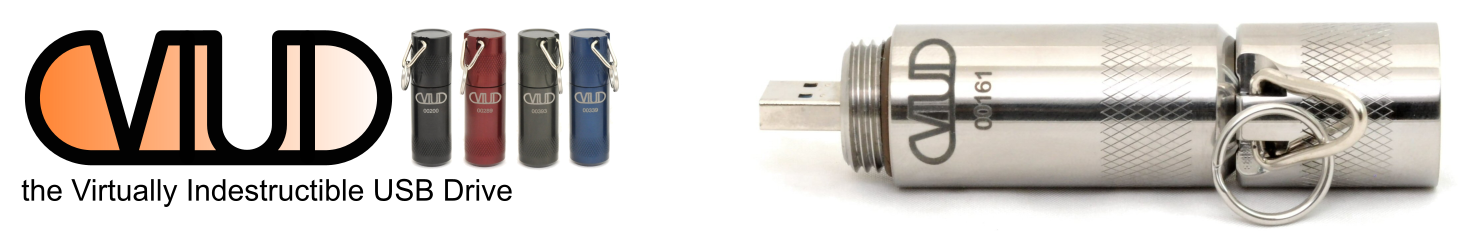

We will perform some initial temperature testing with the one of the third prototypes which has been destined for eventual destructive testing, although we will try to be careful and not destroy it so we can get as much data from it as possible.

Failure Modes

Before going ahead with the testing it may be useful to review exactly how our VIUD may fail at high temperatures:- Plastic in USB connector melts

- USB flash drive fails

- O-rings Melt

- Internal epoxy melts/fails

- Body melts

The primary failure modes we're interested in would be the first two. The plastic melting in particular is the most likely failure as, depending on the exact type of plastic, it occurs at relatively low temperatures of 150-315 °C (300-600 °F) although Wikipedia states a melting temperature for Polyethylene as low as 105 °C (220 °F).

It is difficult to determine at what temperature the flash memory will fail at although it appears to be a gradual process: the higher the temperature the more likely bits will flip by themselves. There is an interesting paper that shows results for accelerated temperature testing in the range of 170-250 °C (340-480 °F) and gives the data retention for their device at 105 °C (220 °F) as 10 years. We can assume from this that the failure temperature for the flash memory is also relatively high and not likely to occur before the connector plastic melts.

Similarly the last three failure mechanisms occur at temperatures above that of the plastic melting point. If Viton o-rings are used they are rated to 200 °C (390 °F) and probably won't completely fail somewhere above that. The epoxy used in this prototype is only rated to 125 °C (260 °F) but again won't completely fail somewhere beyond this temperature and the actual epoxy that is going to used is rated much higher (300 °C, 570 °F). The melting of Aluminum (660 °C, 1220 °F) and Titanium (1670 °C, 3030 °F) is so high as to be mostly irrelevant.

Procedure

The procedure for temperature testing will be relatively simple:- Let test object return to room temperature.

- Let test apparatus achieve desired temperature (if applicable).

- Subject test object to the desired temperature for a set amount of time.

- Cool object after test in water for at least 5 minutes.

- Examine object for any obvious signs of damage.

- Test USB for any new file blocks with errors.

- Test USB contents for any changes in data.

- Repeat test at slightly higher temperature and/or longer period as desired.

The test for bad blocks is done using HD Tune Pro which is a basic drive benchmark and tester. The test for changing bytes during a test is simply done by creating random files that fill the USB and using a MD5 sum to ensure their contents are identical before and after the test.

Test Results

The following table summarizes all the temperature test results so far:

| Test Type | Temperature | Length of Time | Error Test | Bit Change Test | Notes |

|---|---|---|---|---|---|

Oven

|

90 °C (200 °F)

|

5 min

| Passed | Passed | |

Oven

|

120 °C (250 °F)

|

5 min

| Passed | Passed | |

Oven

|

150 °C (300 °F)

|

5 min

| Passed | Passed | |

Oven

|

180 °C (350 °F)

|

5 min

| Passed | Passed | |

Oven

|

200 °C (400 °F)

|

5 min

| Passed | Passed | |

Oven

|

230 °C (450 °F)

|

5 min

| Passed | Passed | |

Oven

|

260 °C (500 °F)

|

5 min

| Passed | Passed | |

Oven

|

290 °C (550 °F)

|

5 min

| Passed | Passed | Case exterior exceeds 100 °C |

Oven

|

290 °C (550 °F)

|

6 min

| Passed | Passed | |

Oven

|

290 °C (550 °F)

|

7 min

| Passed | Passed | |

Oven

|

290 °C (550 °F)

|

8 min

| Passed | Passed | |

Propane Torch

|

1800 °C (3300 °F)

|

10 secs

| Passed | Passed | |

Propane Torch

|

1800 °C (3300 °F)

|

20 secs

| Passed | Passed | |

Propane Torch

|

1800 °C (3300 °F)

|

30 secs

| Passed | Passed | Case exterior exceeds 100 °C |

Propane Torch

|

1800 °C (3300 °F)

|

40 secs

| Passed | Passed | Minor damage to external o-ring |

Propane Torch

|

1800 °C (3300 °F)

|

2 min

| Failed | Failed | Prototype #1, USB plastic melted |

Oven

|

200 °C (400 °F)

|

15 min

| Passed | Passed | |

Oven

|

290 °C (550 °F)

|

9 min

| Passed | Passed | |

Oven

|

290 °C (550 °F)

|

10 min

| Passed | Passed | |

Boiling Water

|

100 °C (212 °F)

|

60 min

| Passed | Passed | Turned Aluminum black |

Wood Fire

|

600 °C (1100 °F)

|

30 sec

| Passed | Passed | Case exterior exceeds 100 °C |

Wood Fire

|

600 °C (1100 °F)

|

45 sec

| Passed | Passed | Damage to external o-ring |

Wood Fire

|

600 °C (1100 °F)

|

60 secs

| Passed | Passed | Damage to external o-ring |

One interesting thing to note is that the boiling water test turned the drive a black color with tints of gold that actually looks rather nice (resembles a black anodized Aluminum). I'm assuming it is something in my water (a very hard water) that turned it this color.

Comparing the Competition

Most USB drives don't have explicit temperature ratings but of those that do the LaCie Xtremkey has the highest:- Operating temp.: 5 to 35°C (41 to 95°F)

- Non-operating temp.: -20 to 60°C (-4 to 140°F)

- Fire test: 30 sec. fire exposure

- Heat test: 200°C (392°F) / 3 min

Since we easily beat both of the listed tests by a considerably margin it is safe to say our VIUD would be the toughest USB drive available for temperature ratings.

Tentative Ratings

We still have to test our final design although I wouldn't expect too different results with the possible exception of the Titanium model performing a little better. We can still estimate our temperature ratings based on the tests so far:

- Operating Temperature: ? to 60 °C (? to 140 °F)

- Storage Temperature: ? to 90 °C (? to 200 °F)

- Air Storage: 290 °C (550 °F) for 5 minutes

- Boiling Water: 100 °C (212 °F) Indefinitely

- Wood Fire: 1 minute exposure (600 °C, 1100 °F)

- Propane Torch: 40 seconds exposure (1800 °C, 3300 °F)

The operating and storage temperatures may be changed by the specifications of the USB flash memory used. Next up will be testing the cold side of the temperature scale which should be interesting to see how low we can go.

No comments:

Post a Comment